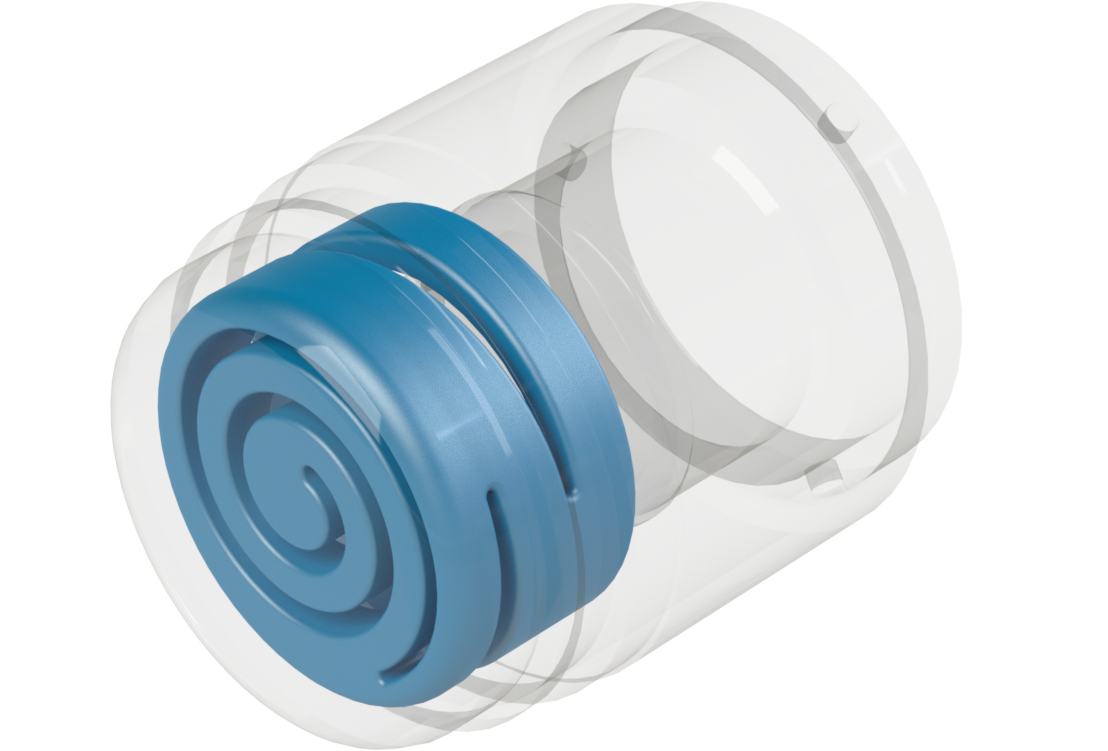

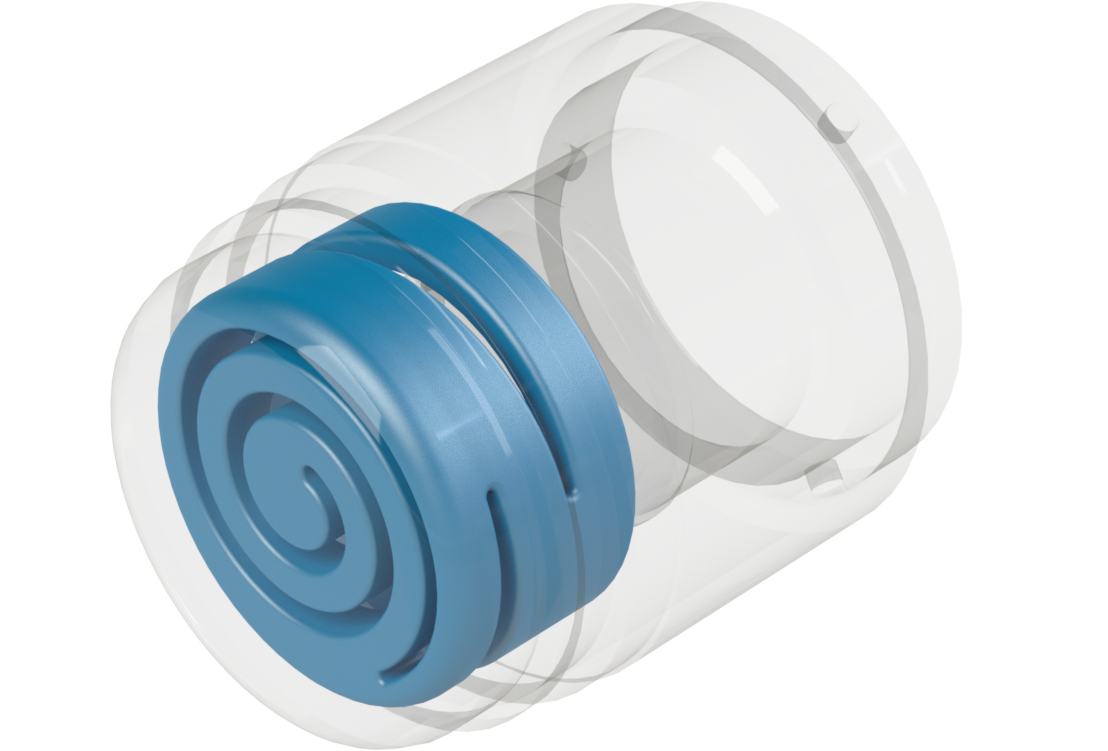

iTherm® PISTON/PLUNGER

iTherm® Piston/plunger is a single HPDC component with specially designed internal cooling system. Using it results in substantially extended piston lifetime (up to 3x) and less porosity in the cast product.

iTherm® Piston/plunger is a single HPDC component with specially designed internal cooling system. Using it results in substantially extended piston lifetime (up to 3x) and less porosity in the cast product.

iTherm® Piston/plunger is produced using tool steel forged or rolled bars and HTS proprietary additive manufacturing technology.

It is a single body component with equal mechanical properties as tool steel monoblock.

Cooling channels can be freely designed according to the cooling/heating requirements of the product, not by the limitations of using the conventional drilling method.

There are different iTherm® Piston models for different machine sizes and applications.

It is highly customizable to specific customer requirements.

In comparison with the conventionally made pistons, iTherm® gives you extra flexibility to bring cooling channels near the critical zones of the piston.

In comparison with the conventionally made pistons, using iTherm® Piston, the heat is distributed much more evenly over the surface, so the piston is cooling down more evenly and faster.

Conventional die casting components

iTherm® die casting components

With iTherm® Piston, the conformal cooling of the steel allows the heat removal rate to exceed that of BeCu tips while extending its lifetime due to low transient stresses in the membrane.

Our customers have reported more than 120.000 shots lifetime of iTherm® Piston (with 3x ring replacements).

iTherm® Piston after 120.000 shots

In the pour phase of the cycle, iTherm® Piston temperature is higher compared to other pistons, (low heat capacity of steel membrane) preventing premature aluminium solidification.

Due to high iTherm® Piston cooling effectiveness, extreme temperature drop occurs in the injection/pressurization phase, resulting in rapid biscuit cooling.

Due to the supreme thermal management characteristics of iTherm® Pistons, their usage results in up to 15% shorter cycle time.

Based on the application, die casting machine size and type of cast part, there are different iTherm® Piston models, tailored to make the difference.

MACHINE TYPE

medium to big machines,

70 – 160 mm (3,00“ up to 6,00“)

APPLICATION

all applications/structural parts

iTherm® Piston V2.1

MACHINE TYPE

medium to big machines,

70 – 160 mm (3,00“ up to 6,00“)

APPLICATION

all Aluminium and Magnesium applications/structural parts

iTherm® Piston V3.1

MACHINE TYPE

large machines

120 – 180 mm (4,50“ up to 7,00“)

APPLICATION

all applications/engine blocks and other large castings

iTherm® Piston V4.1

| DIMENSION | RANGE (mm) |

|---|---|

| Diameter | 70 – 180 |

Based on specific customer needs, larger pistons can be produced.

iTherm® Pistons are made using forged or rolled tool steel bars produced in the EU.

We also manufacture a selection of different piston rings for iTherm® Pistons. Read more…

Fill in the form below and we will get back to you