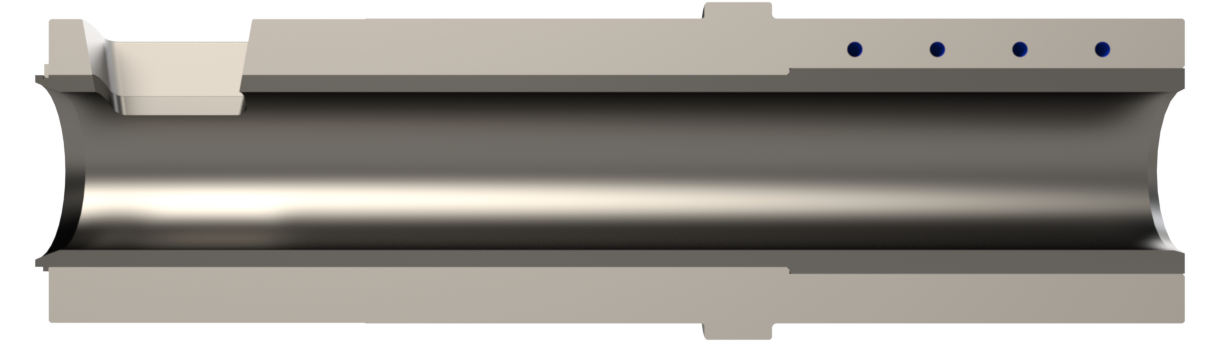

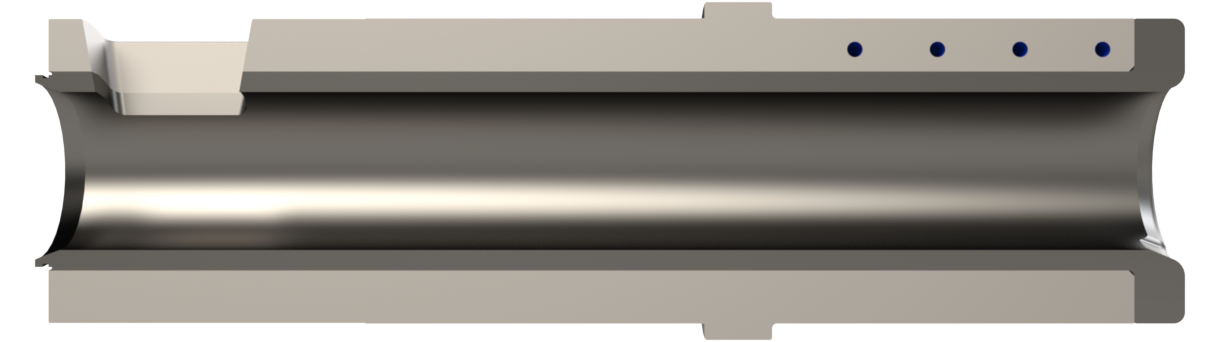

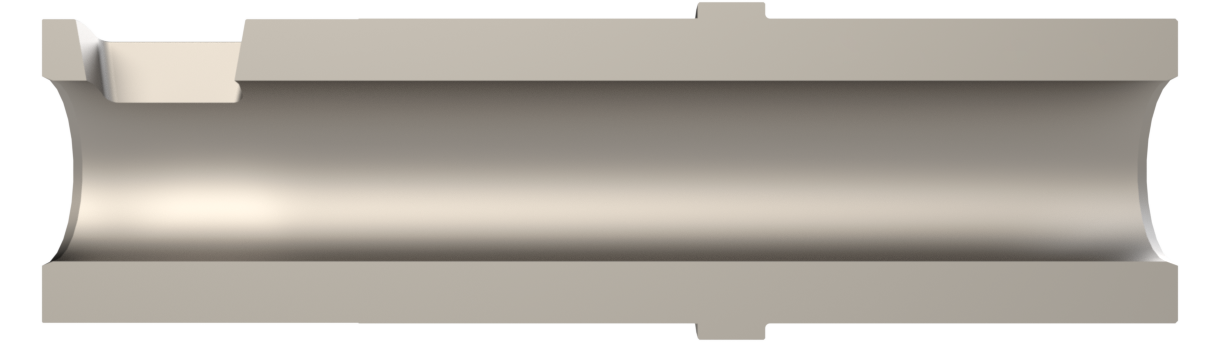

The shot sleeve is bored to form an envelope and a special integral insert/liner that covers the whole length of the sleeve gets inserted into the envelope

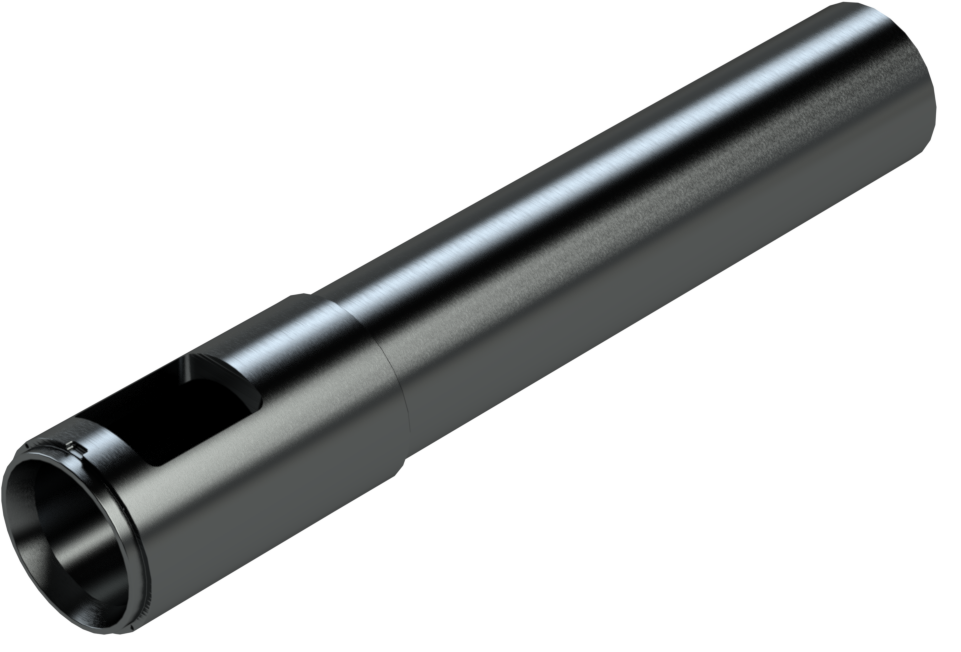

This way sleeve/envelope never comes into direct contact with molten alloy, so sleeve replacements are completely avoided. Insert/liner is the only component that needs to be replaced

Insert/liner gets replaced very quickly, in the case of smaller machines, it can be done directly on the machine, while in the case of larger ones, there is a special replacement tool we provide.

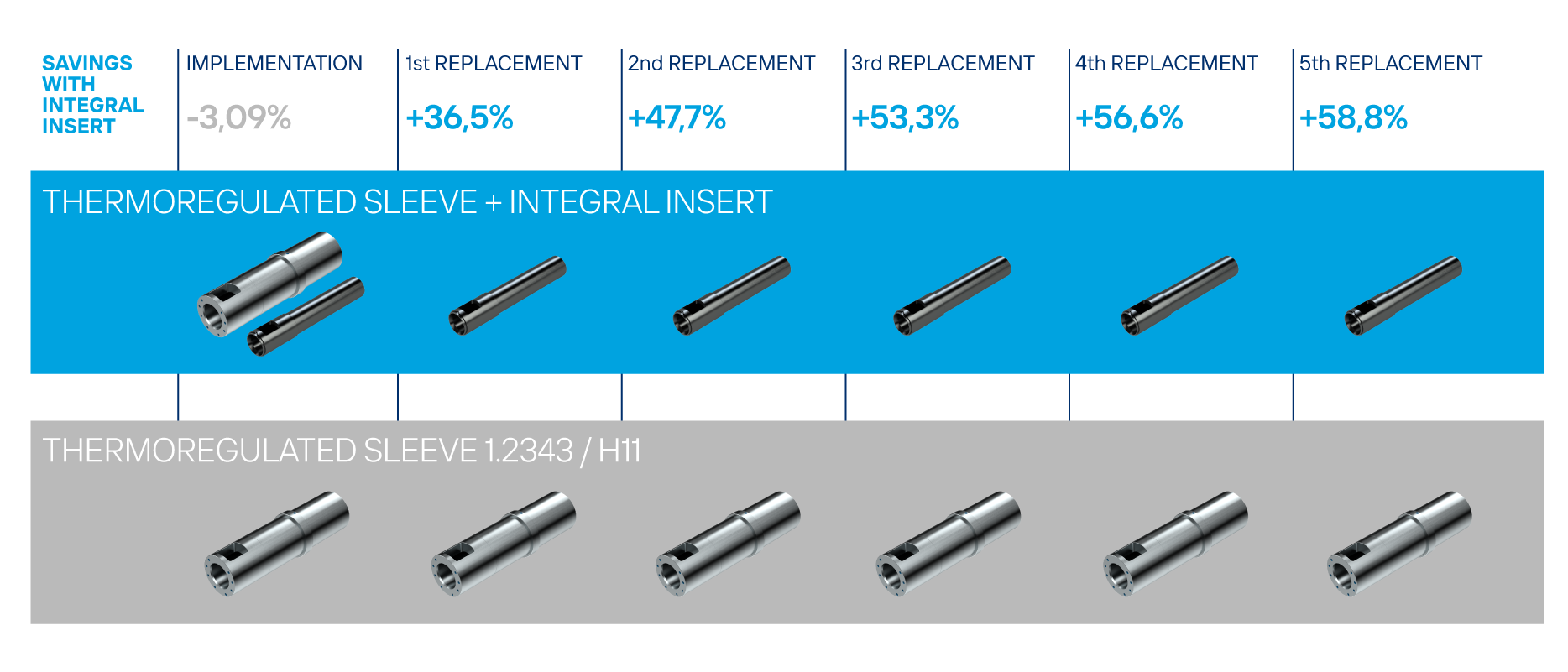

When using an integral insert/liner the cost of the envelope occurs only at the point of implementation.