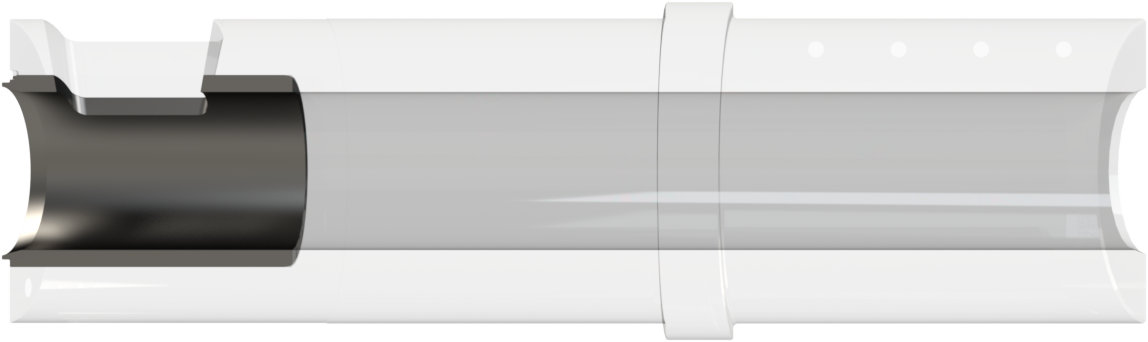

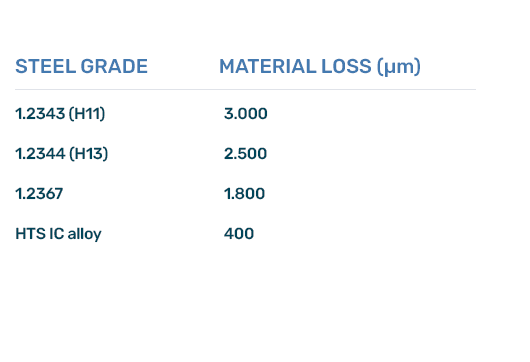

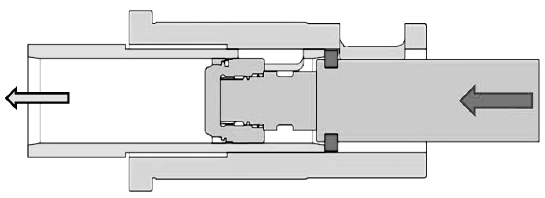

Shot sleeve function is to hold molten aluminium while it is being pushed into the die by the plunger. Usually, it is made using various types of hot work-tool steels, ranging from 1.2343/H11, 1.2344/H13 to 1.2367, and nitrided to ensure wear resistance.

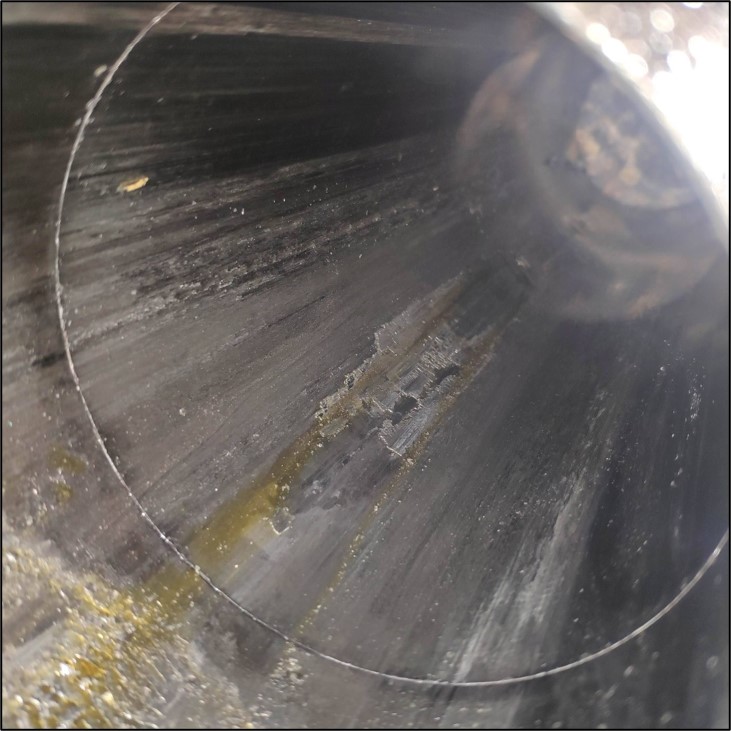

Casting process-wise it is important that the plunger consistently moves through the sleeve, while a seal between the shot sleeve and the plunger is ensured.

With constant temperature changes and components’ thermal expansion during the casting cycle, the gap between the plunger and the sleeve is changing and in cases when it surpasses 0.1mm, the molten aluminium can flow by, form a compound and cause additional wear on both, the sleeve and the plunger. This results in extensive wear, premature failure and unplanned production stoppages.

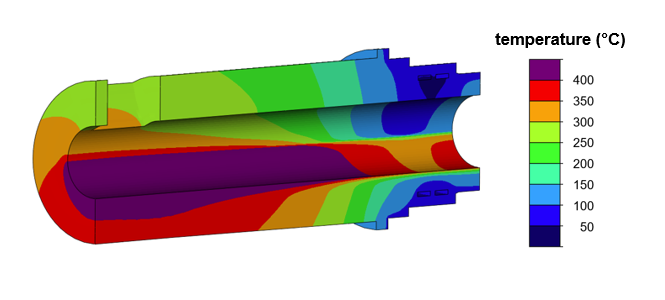

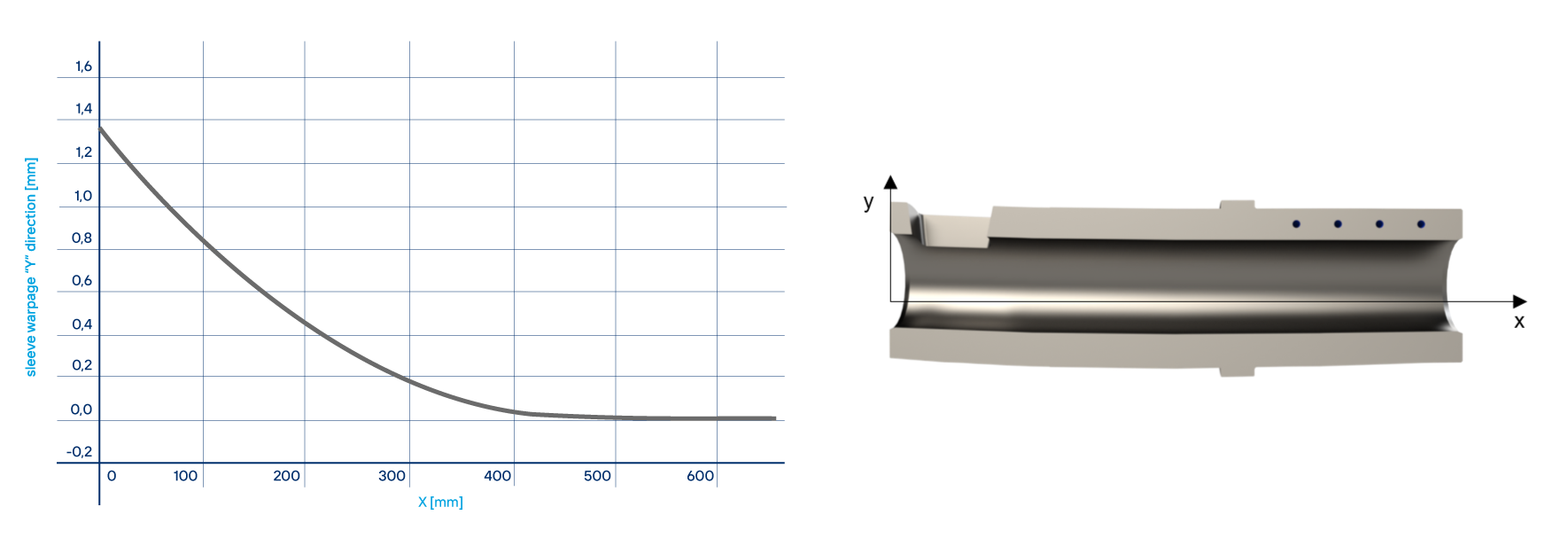

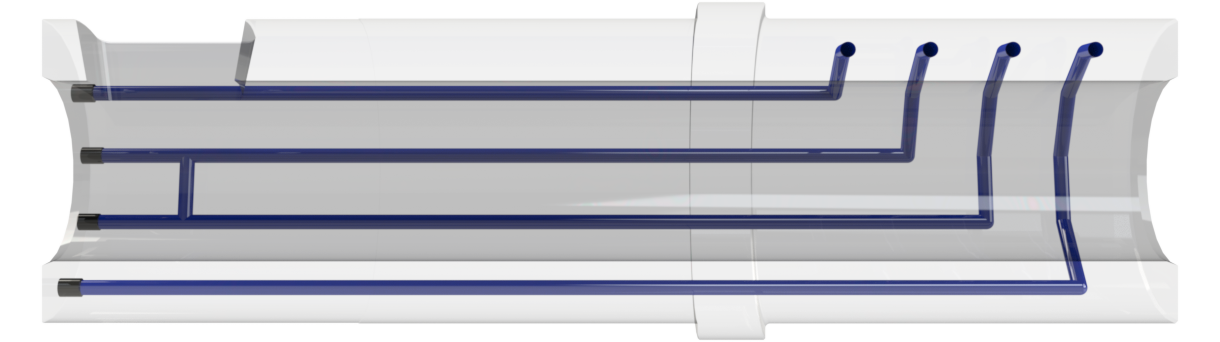

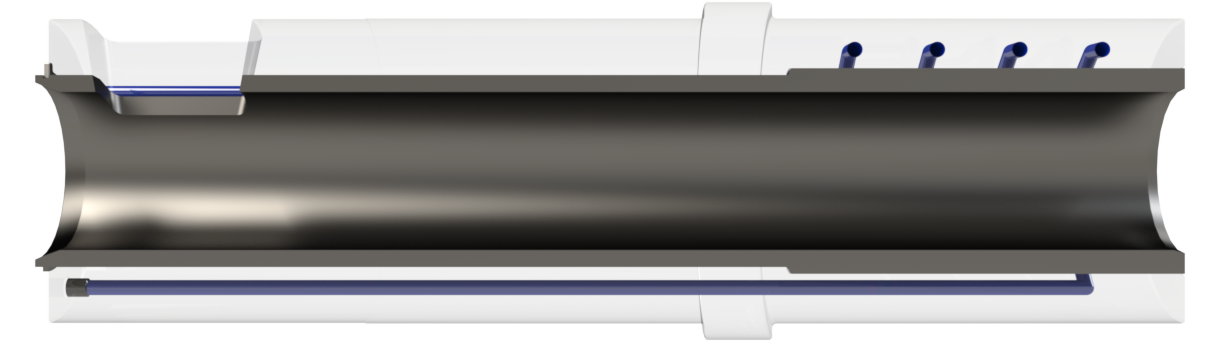

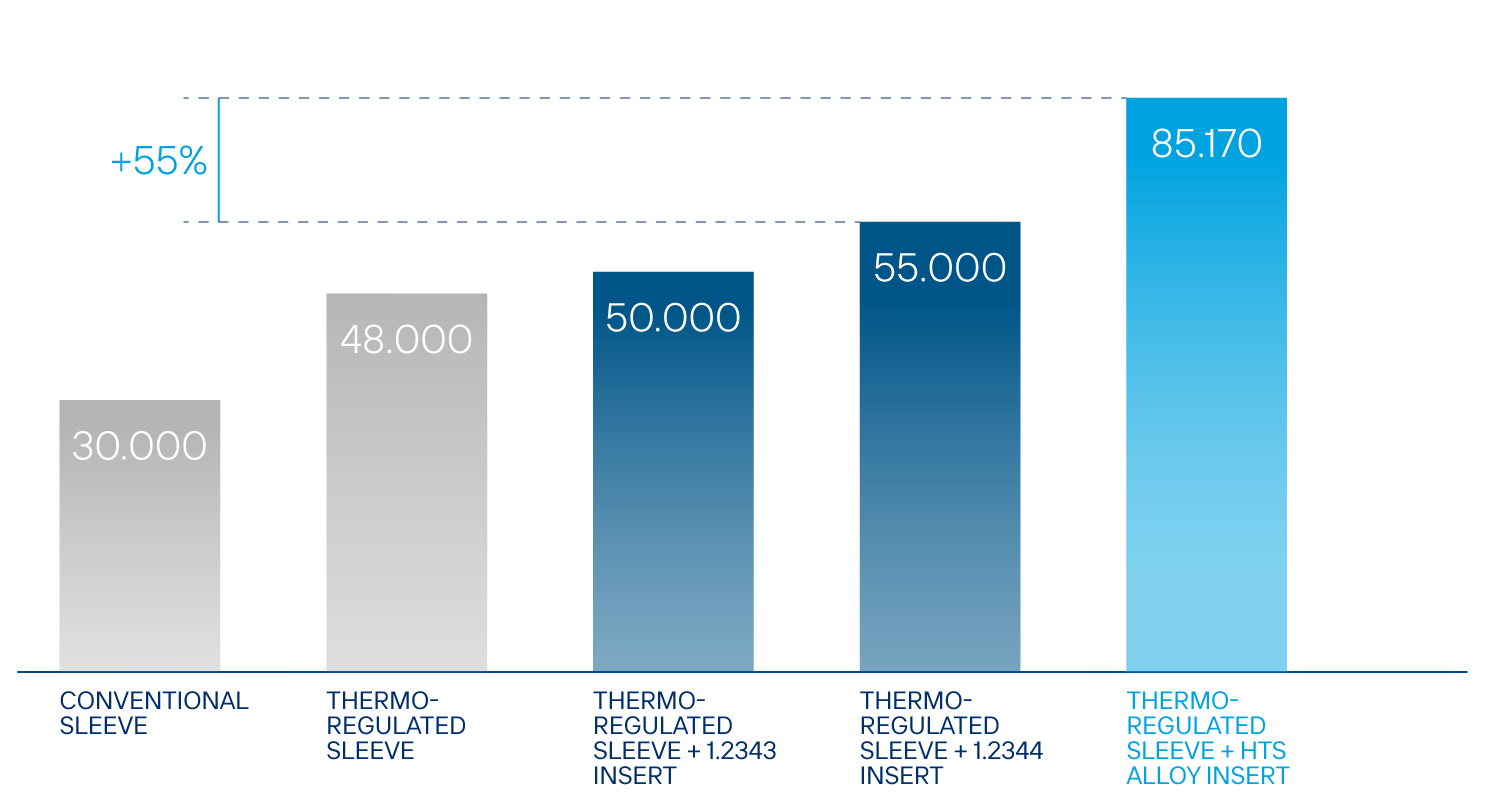

Effective management of the gap between the sleeve and the plunger mainly comes down to two areas, good thermal management of sleeve and plunger, and dimensional stability of the sleeve.

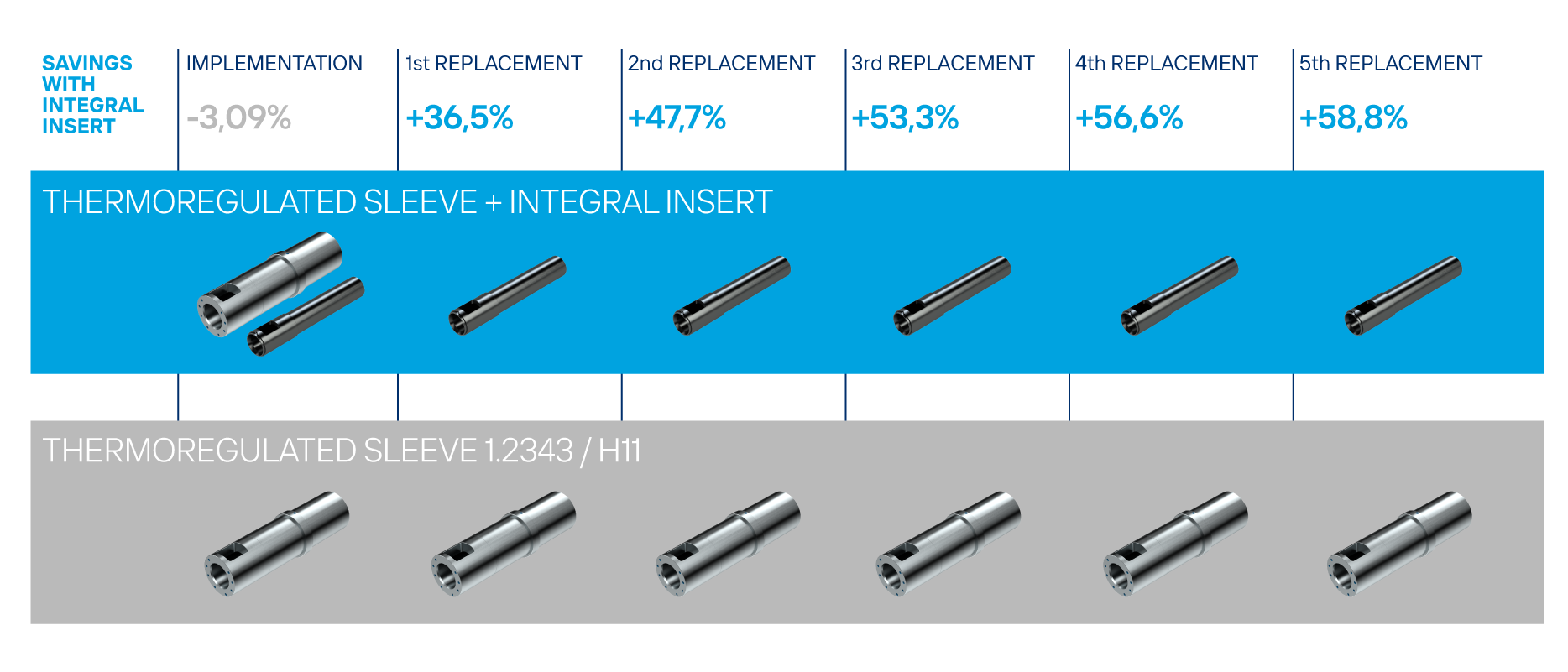

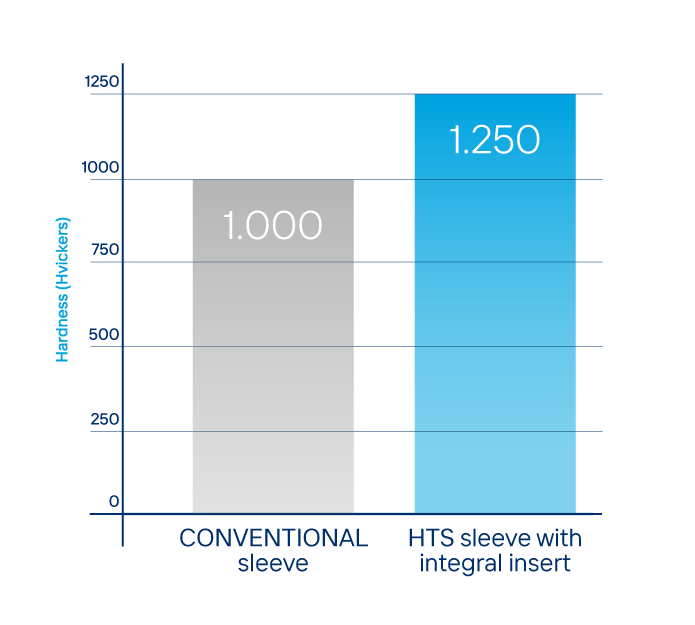

Below we discuss how to ensure maximum dimensional stability of the sleeve to assure optimal cost efficiency.